Filter press Cake | Filter Cake Discharge Methods

Filter Cake Discharge Methods

VisitCount 61

Filter Press Cake

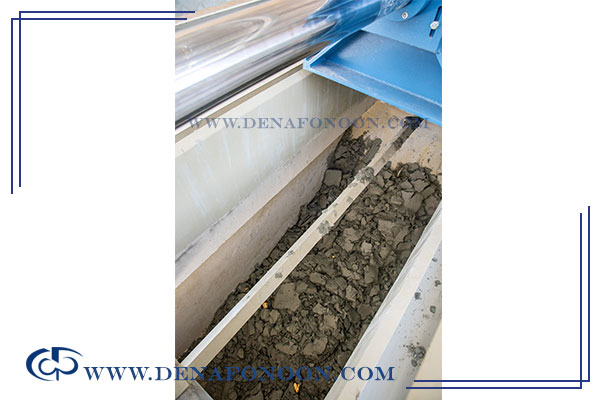

Filter press cake refers to the solid material that remains between the plates of a filter press after the filtration cycle is completed. This cake is a crucial byproduct in various industries, indicating the efficiency of the filtration process and often serving as a raw material for further applications.

Formation of Filter Press Cake

During the filtration process, slurry is pumped into the chambers of the filter press. The filter cloths within the press capture solid particles, allowing the liquid (filtrate) to pass through. Over time, these solids accumulate and compact under pressure, forming a dense, porous layer known as the filter cake. In some systems, additional dewatering steps, such as compressed air or membrane squeezing, are employed to further reduce the moisture content of the cake

Characteristics of Filter Press Cake

The properties of filter press cake are influenced by several factors:

Moisture Content

Determined by the slurry composition and the filtration process parameters.

Permeability and Porosity

Affected by the particle size distribution and the packing density of the solids.

Cohesiveness

Indicates how easily the cake can be removed from the filter press.

These characteristics are essential for assessing the efficiency of the filtration process and the potential for further processing of the filter cake

Methods of Cake Removal

Filter presses can be categorized based on their operation and cake removal methods

- Automatic Filter Presses: These systems utilize mechanical or pneumatic devices to remove the cake automatically after each filtration cycle.

- Manual Filter Presses: Commonly used in laboratory settings, these presses require manual intervention to remove the cake, often using tools to dislodge the solids without damaging the filter cloths.

The choice between automatic and manual systems depends on the scale of operation and the specific requirements of the filtration process.

Applications of Filter Press Cake

Filter press cake has diverse applications across various industries

- Mining and Metallurgy: Used in the recovery of valuable minerals and metals from ores.

- Chemical and Pharmaceutical Industries: Serves as a raw material for the production of chemicals and pharmaceuticals.

- Food and Beverage Industry: In some cases, the cake is processed into animal feed or used in the production of biofuels.

- Environmental Management:The cake can be treated and disposed of in an environmentally friendly manner. In some cases, it is recycled into useful products, such as being processed into bricks for construction purposes, as explained during the brick process filter press.

Conclusion

Filter press cake is a significant byproduct of the filtration process, with its properties and applications varying across industries. Understanding the formation, characteristics, and potential uses of filter press cake is essential for optimizing filtration processes and exploring sustainable practices in waste management and resource recovery.